Made in Canada – inspired by Sweden

Canada can solve parts of the housing shortage and climate challenges by build industrially in wood with a national supply chain and at the same time become more independent of the United States.

Canada has the building materials, factories, and personnel needed.

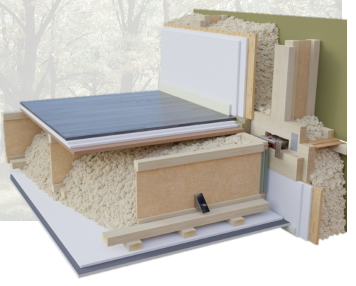

Our system consists of factory-made panels such as walls and floors, which are assembled on site under a weather protection that has integrated lifting aids. The weather protection creates a factory-like environment and becomes a mobile factory that enables industrial production with a paced flow also on site. Building with panels instead of modules greatly reduces the need for investments and provides significantly greater freedom to design the buildings to meet local needs. Wall panels are very flexible and floor structures can handle free spans up to 9 meters and with panels you have almost the same freedom of design as with traditional site construction. Panels also require less transports than modules.

We have knowledge of how to build industrially in wood in a resource-efficient, fast and environmentally friendly way.

Let’s explore how we together can take advantage of these business opportunities!

Our mission

Visionary Woods Sweden shall inspire the world to construct Zero-CO2 buildings in wood. By proof-of-concept show that it can be done in big scale, with low material usage and to affordable prices due to an effective and industrialized process.

Our offer

To be able to build many homes in a short period of time, you need an industrial production system. Our system provides the opportunity to build apartment buildings in wood up to 8 storeys in large volume at a very low investment costs.

Building system with I-Joists up to 8 floors

Build up to eight floors with a light wooden frame! The system consists of panels, walls and floors, where external walls and walls separating apartments, are load-bearing and the floor structures can handle up to nine meters of free span, which provides a great deal of architectural freedom when it comes to design the buildings. The system meets high demands on fire, sound, statics and energy consumption.

Low CO2 footprint

More than 90 percent by volume of load-bearing structures consists of wood, including the load-bearing frame of I-joists, wind-stabilizing boards of wood and insulation of wood fiber. The system has one of the lowest CO2 footprints of industrial building systems in the world, and it can be made even better by replacing painted gypsum boards with coloured clay plaster.

Raw materials from Canada

Canada as a country is very rich in natural resources and the raw materials needed to build our wooden houses are mainly to be found within the country’s borders.

Factory Production in Canada

Panels can be manufactured in many existing Canadian factories. Equipping the factory to manufacture panels for the building system requires much less resources than a modular factory with the same capacity.

Weatherproof construction on site

Precipitation in connection with the installation of wooden houses causes very high costs every year. Building with weather protection is a prerequisite for an industrial process and ensures a good quality of the finished product.

Industrial process based on Lean

At the factory, production is most advantageous set up as line production, where the products flow through different stations in the factory in a paced flow. On site, different teams are set up that work on a limited task, similar to a station in a factory, and the team move through the product, the building, in a paced flow. Each Team performs the same tasks in each zone, a zone can correspond to an apartment and the pace is normally one day per zone. All tasks that the Teams perform are described in detail in so-called element sheets. In this way, it is easier to train new people to work in the system and it is also not necessary to have the same prior knowledge as on a traditional construction site. They also work with other Lean tools such as 5S, daily pulse meetings and continuous improvements. In this way, you can create industrial conditions also on site, which secures time, work environment and quality.

Prefabricated bathrooms

Manufacturing completely finished bathrooms in a factory reduces costs, among other things, because you reduce the work on site and at the same time you reduce the risk of water damage during the life of the house.

Digital support systems

The design work is done in 3D and to create a complete and accurate 3D model of the entire building and its systems, which is a prerequisite for the industrial system to work. We usually say that you build the original digitally and the physical building becomes an exact copy of that. The drawing work is largely automated, and you not only simulate exactly what each part should look like, but also where and when it should enter the process. When the model is ready, it is connected to ERP and MPS systems where each part is handled as a unique item, which facilitates purchasing, production and accounting. In this way, it becomes possible to handle large amounts of data with minimal effort of working time.

Installations

When it comes to heating and ventilation, it is possible to use different configurations depending on the local conditions. Distribution of heat can take place with, for example, radiators or underfloor heating. Fan-reinforced natural ventilation in combination with passive geothermal heating is a conceivable combination if you want a simple and uncomplicated ventilation system with low maintenance costs.

Scalability

Everything we develop is based on the premise that it should be possible to carry out on a large scale.

Service Overview

Get an insight into our services, which together with you can be transformed into good business opportunities in the Canadian market.

Concept development

We help you implement a complete production system for wooden houses adapted for the Canadian market.

Training

We train the team’s staff.

Construction Design

We carry out complete design of the buildings and plan the entire process.

Implementation of projects

We assist with support throughout the construction process..

Industrial Production System for Wooden Houses

An efficient and scalable process requires a number of components, below an overview of our offering.

Business management system

In-house developed ISO-based business management system as the basis for the business.

LEAN

Proprietary Lean Excellence System to build on.

3D modeling

Concept for collaboration where each discipline delivers a number of IFC models that are then integrated into a main model, minimizing the need for collision controls.

Architect’s Guide

Instructions to architects on how to design in order for production to function optimally.

Material import

We help with importing the products that are not available in Canada from Europe, which provides an opportunity for extended independence from the United States.

Digital System

Connection between 3D model and ERP/MPS system. Item management, purchasing, production planning, MPS, accounting and follow-up.

Production data

Digital control files for NC machines that manufacture components as well as drawings and descriptions.

Planning

Paced flow in line production at the factory and paced flow on site with zoning and pace trains. The planning is based on detailed element sheets and sequences.

Factory layout

Support for the good functioning of factory production.

Training

Training of key personnel.

Weather protection

In-house developed weather protection where the final roof is used as weather protection. Lifting aids allow for a continuous assembly process.

Industrial process

We have a detailed process from start to finish that we can provide to you to start from.

Building systems

In-house developed building system with a focus on cost-effective solutions and environmentally friendly materials. Lowest CO2, good sound reduction and fire properties.

Support

We offer support for your team during the production process.

Quality Control Program

We offer support for quality checks

Testimonials from our partners

”The concept is one of the most environmentally friendly industrial concepts developed in Europe.”

Maria Block, Architect and author of the book ”Byggekologi”

”The system delivers some of the best acoustic properties on the wooden house market and can compete with concrete systems in terms of acoustics.”

Clas Hagberg, Acouwood AB

”Insulation of wood fiber insulates well, burns poorly and handles moisture in a safe way, contrary to popular belief. Despite a higher material price, wood fibre insulation is cheaper when installed than several of its competitors. We have many years of experience and good practical references.”

Reidar Berglund, Svenska Termoträ AB

”By building in a system, the design process is simplified with each new project. Eight floors with I-joists are no longer a problem.”

Björn Johansson, Expert tall wooden buildings, Bjerking AB

”We have delivered thousands of finished bathrooms without any problems with water damage caused by our product. Finished bathrooms facilitate work on site and make the process of completion shorter.”

Peter Lundmark, Podcomp AB

”Building a factory for panels is easier and much cheaper than a factory for modules, and you get up to the intended capacity faster. In addition, it is easier to produce customized solutions with panels than with modules.”

Erik Nord, BNC Maskin AB

”ABB/Wago’s electrical system with pre-wired cable and appliances saves 40% copper and is much faster to install than traditional electrical systems.”

Dusko Davidovic, ABB

”An excellent way to avoid technically complicated mechanical ventilation and comfort cooling systems is to use free geoenergy instead. By using the operating strategy Needs and Seasonal Ventilation, the supply air passively passes through a ground-mounted ventilation culvert under the building, the supply air is supplied with sufficient heat energy and cooling energy for a good and healthy indoor climate all year round.”

Torkel Anderson, ByDemand AB

”Clay plaster is an alternative to both clay boards and gypsum plasterboard as fire protection in wooden houses. If you choose the right clay plaster instead of board, you get a uniform surface to work with. In addition, you get a significantly lower CO2 footprint.”

Oscar Nymberg, Lera i Norden AB

Contact us for more information

Do not hesitate to contact us for a discussion.